GAINA MARINE

&

NON-KETSURO

(Non-Condensation)

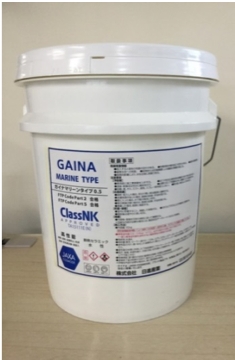

GAINA MARINE

GAINA MARINE is a sound- and heat-insulation coating for marine use developed and commercialized by Kashiwa with the cooperation of Nissin-Sangyo Co. Ltd.

GAINA, based on which GAINA MARINE was developed, is a coating developed by JAXA (Japan Aerospace eXploration Agency) to cover the rocket nose section to protect H-Ⅱ rocket and satellites loaded on it from the friction heat when launching. That technology was diverted by Nissin-Sangyo Co. Ltd to civil use.

GAINA MARINE has passed the surface burning test specified by FTP Code Part V and is certified as a fire-retardant coating for various applications.

Features

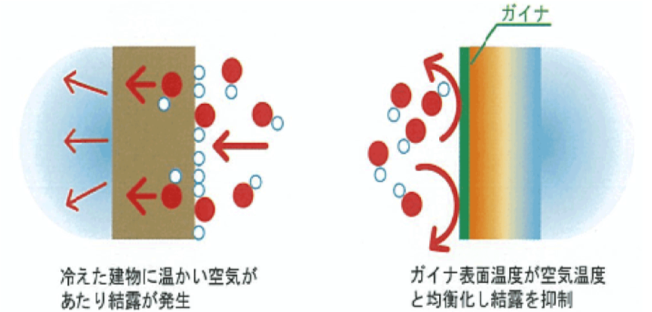

GAINA is made of hollow ceramic particles which tend to accord with surrounding temperature, minimizing heat transfer. This unique characteristic effectively controls the temperature and gives heat insulating effect anytime no matter exterior or interior it is used for.

It is also proof against dew condensation, which is caused by moisture contained in hot air as it is cooled down to its dew point due to heat transfer to cold surface exposed.

Application Examples

GAINA has been used for various onshore applications, such as residential buildings, factories, trains, automobiles, and cultural architectures.

GAINA Marine has also been adopted as a heat-insulation coating for decks, exterior of accommodation space and ceiling of car holds, and highly regarded by so many ship owners.

The comparison test conducted on an accommodation deck of a PCC proved that GAINA had superior heat blocking and insulation property than a similar type of coating of other brand.

NON-KETSURO

NON-KETSURO is developed based on GAINA, specifically to have improved anti-condensation property.

This product is the mixture of aqueous acrylic resin and ceramic aggregate that excels in moisture absorption and dissipation, which enables it to create flexible coating film with superior anti-condensation property.

NON-KETSURO consists of primer (7kg) for undercoat and top coat (15kg) for finishing.

Application Examples

It is used at sections where dew condensation is highly expected, such as refrigerated trailers, air outlet of air conditioners, ceiling of bathrooms or kitchens.

For marine use, it is often applied on tanks and piping running refrigerant where dew condensation is expected.